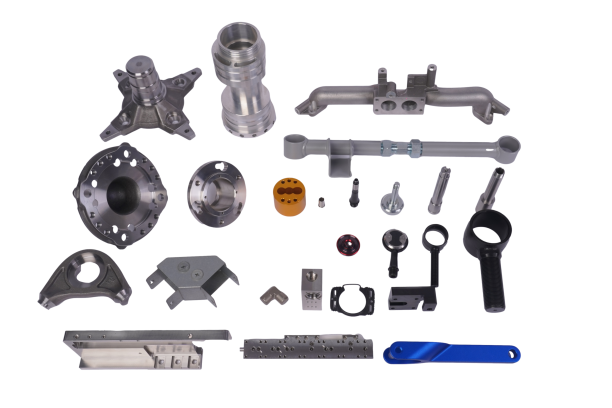

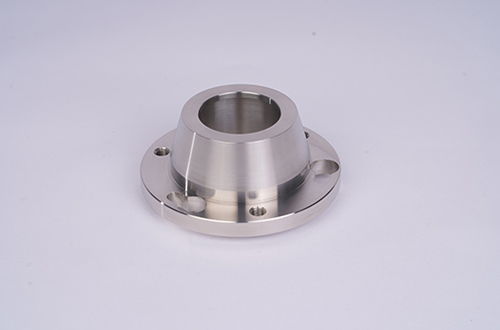

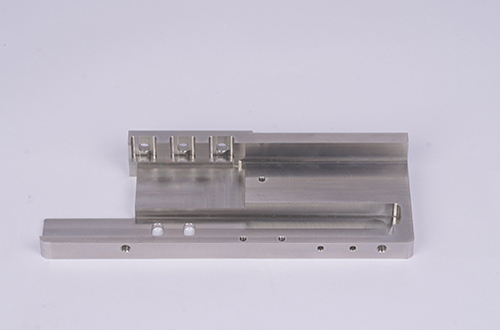

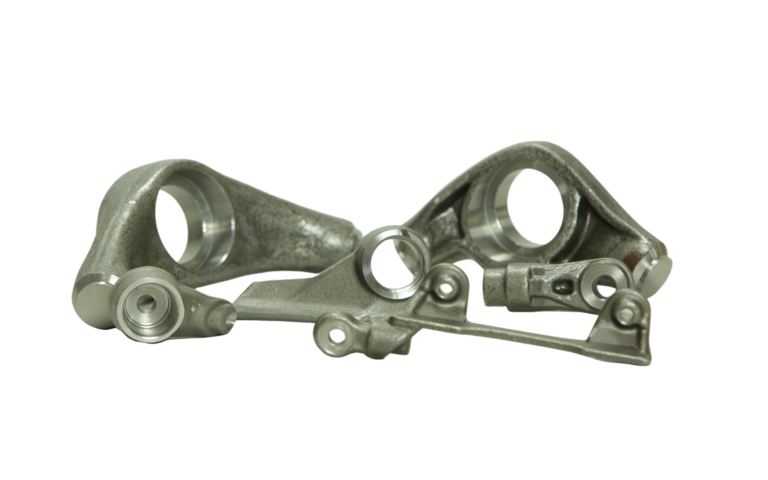

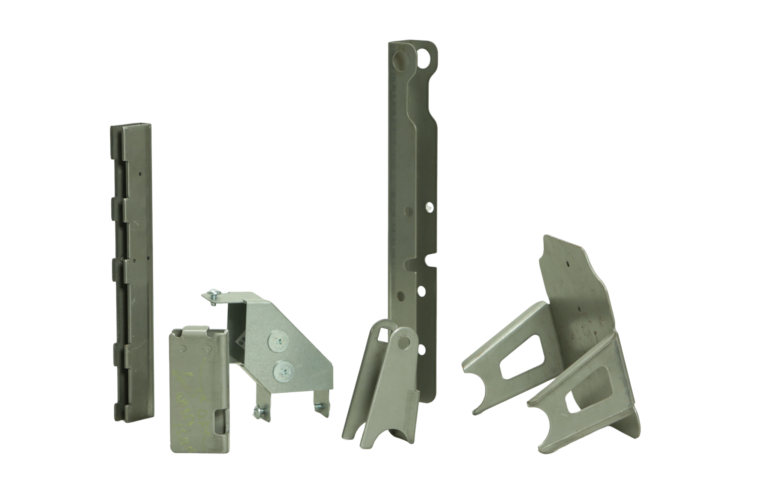

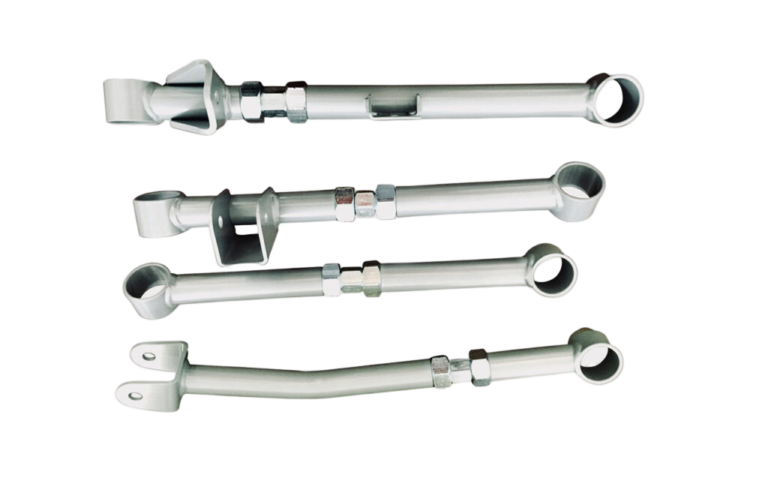

Machining Tenology

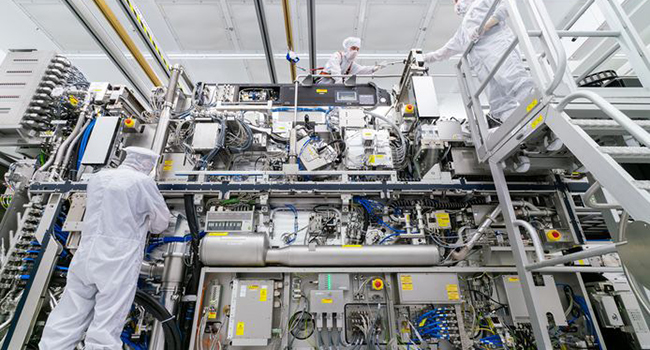

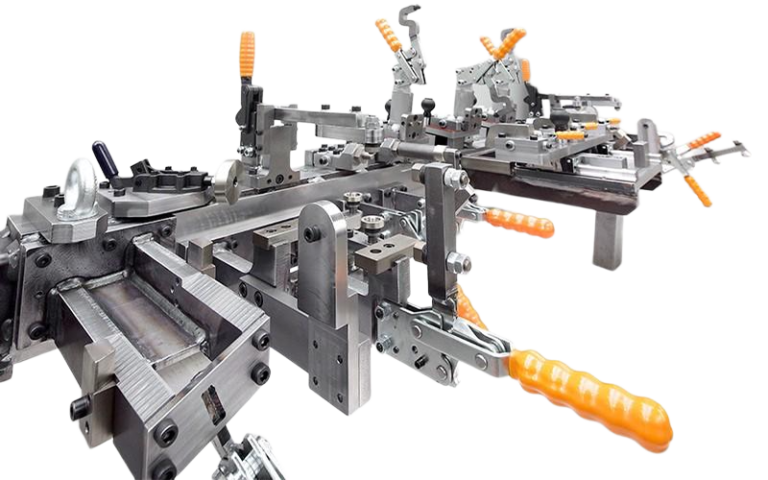

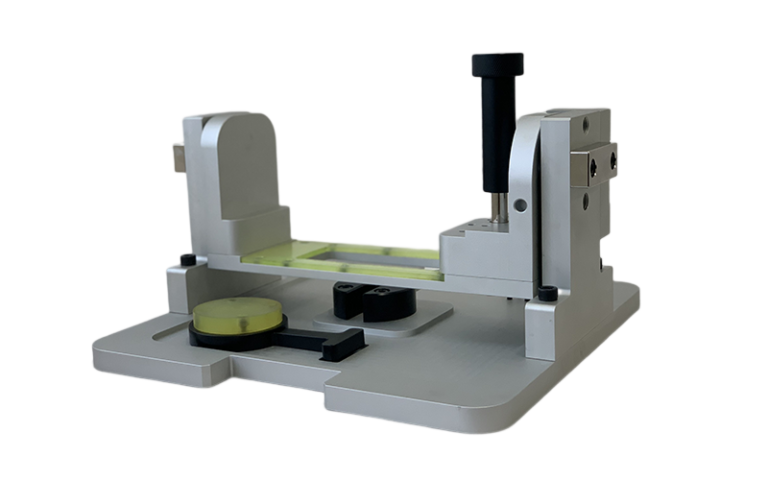

ANCL can manufacture from raw material purchasing to machining, heat treatment, painting/galvanizing, polishing and cleaning, etc. Machining with stable precision by always controlling the material. materials, condition of machines, human resources, processing environment, etc. At the same time, design – manufacture jigs to support production and inspection. Improve and streamline the stages to produce quality products in the shortest time. We are constantly trying to develop every day to match the changes of the times and meet the new needs of our customers.